|

| Category 2 |

|

| Installation areas liable to be endangered by explosive atmospheres | Pumps intended for use in areas in which explosive atmospheres are likely to occur |

|

| G (gas) | D (dust) |

|

| 1999/92/EC | Zone 1 | Zone 21 |

|

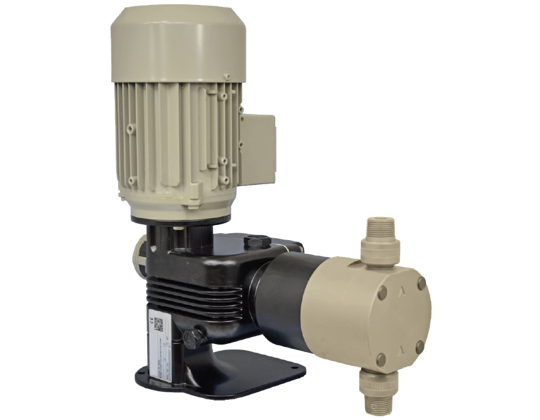

ATEX-approved pumps are for use in

potentially explosive atmospheres.

Explosive atmospheres consists of air and combustible matter, such as gases, vapours, mists or dusts in which the explosion spreads after ignition.

We offer explosion-proof or dust-ignition-proof motors in accordance with the ATEX directive

2014/34/UE.

ATEX-approved pumps can be used in areas (zones) classified according to the directive 1999/92/EC.

- Double ball check valve

- 3-phase motor

- Aluminium enclosure

- Spring return mechanism

- Stainless Steel (AISI420) Plunger

- 3-PHASE 0.18KW 1660G 60 Hz GAS

- 3-PHASE 0.37KW 1660G 60 Hz GAS

- 3-PHASE 0.55KW 60 Hz GAS

- 3-PHASE 0.25KW 1325G 60 Hz DUST

- 3-PHASE 0.37KW 1375G 60 Hz DUST

- 3-PHASE 0.55KW 60 Hz DUST

POWER SUPPLY 12/24 V

All metering pumps flow rates are referred to 230 VAC

(50-60Hz) and 115 VAC (50-60Hz) mains.

For other power supply (24 VDC/VAC and 12 VDC) please enquire.

STANDARD KIT

Metering pumps are provided with:

- PVDF injection valve,

- PVDF foot/filter valve,

- PVDF level probe (except for CO models)

- 2 m delivery hose (PVDF, except for V, VA and VMS, VMSA series),

- 2 m suction hose (PVC flexible),

- 2 m outgassing hose (PVC 4x6).

Polymers pump series are provided WITHOUT injection valve, foot/filter valve and level probe.

Pumps with Stainless Steel pump head are provided WITHOUT accessory kit.

Self-venting pumps series have PE outgassing hose.

EXTERNAL LEVEL ALARM (N.O. free contact)

MF and DC (except VMS MF) pump series are equipped with external level alarm. Optional for the others.

CHEMICAL COMPATIBILITY

Refer to chemical Compatibility Table.

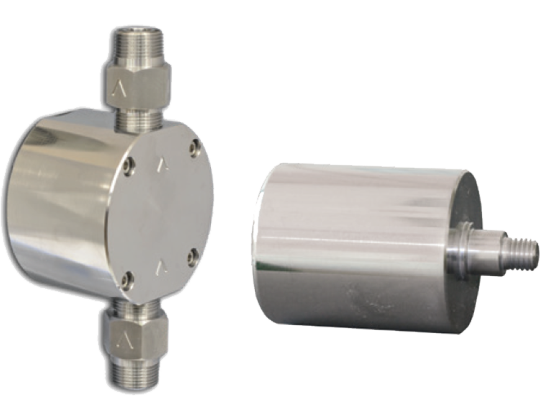

CERAMIC BALLS

EMEC standard check ball valves for all pumps series are made of ceramic, except for high viscosity liquid pumps (PTFE check ball valves).

PTFE or AISI 316 check ball valves are available on demand.

QUIET PUMP

V and K series (on some capacities) quiet pump availables.

WORKING TEMPERATURE

-10°C-+45°C (14°F-113°F)

INPUT FOR WATER METER WITH HALL EFFECT

Available on MF series pumps input for water meter with Hall effect (on demand).

ABBREVIATIONS

| BS | BRASS |

| C276 | Hastelloy C276 |

| EP | Ethylene Prophylene |

| FP | FKM B (Fluoroelastomer B) |

| POM | Acetal Copolymer |

| GL | Borosilicate |

| PP | Polypropyilene |

| PTFE | Polytetrafluoroethylene |

| PVDF | Polyvinyldene Fluoride |

| SI | Silicone |

| SS | Stainless Steel |

| WAX | Nytrile |

| PMMA | Polymethyl Methacrylate |

GLOSSARY OF THE TERMS USED IN THE TABLES

| DOSING SYSTEM | - Constant: regular pump feeding as configured by the user.

- Proportional: proportional feeding based on an input signal. |

| LEVEL CONTROL | Tank low level stops the pump. |

| FLOW SENSOR INPUT | Flow sensor input SEFL (sensore di flusso) for dosing system control. |

| STAND-BY INPUT | pump enabling/disabling control |

| ALARM OUTPUT | Contact relay switched by pump's anomalies |

| STROKE SPEED (FREQ.) ADJUSTMENT | Injection frequency control |

| STROKE LENGTH ADJUSTMENT | Injection volume control |

| DIGITAL SIGNAL | Digital input (voltage free contact) for instrument or water meter connection |

| CURRENT SIGNAL (0/4MA=0 PULSES; 20MA=MAX PULSES) | mA analogic input for instrument or water meter connection |

| LEVEL ALARM OUTPUT | Contact relay switched by tank low level |

| CC/S | Max cc per stroke. |

| CP | Standard pump head model (PVDF). |

| PMMA | Extra price for Polymethyl Methacrylate pump head (PMMA). |

| SS | Extra price for Stainless Steel pump heads, without accessories and hoses (see "SS ACCESSORIES" table). |

| HOSE (suction/outgassing) | Extra price for PVDF suction and outgassing hoses. |

| HOSE | Extra price for PVDF suction, delivery and outgassing hoses. EMEC recommends using PVDF hoses when dosing concentrated sodium hypochlorite. |

HOSES WORKING PRESSURE

| Hose | Working pressure (bar) | Breaking pressure (bar) |

| 20°C | 30°C | 40°C | 50°C | 20°C | 30°C | 40°C | 50°C |

| 4x6 mm PE 230 | 12 | 10.5 | 8.5 | 6.2 | 36 | 31.5 | 25.5 | 18.5 |

| 4x8 mm PE 230 | 19 | 15.7 | 12 | 7.5 | 57 | 47 | 36 | 22.5 |

| 6x8 mm PE 230 | 8.6 | 6.8 | 4.8 | 2.3 | 26 | 20.5 | 14.5 | 7 |

| 8x12 mm PE 230 | 12 | 10.5 | 8.5 | 6.2 | 36 | 31.5 | 25.5 | 18.5 |

| Hose | Working pressure (bar) |

| 20°C | 30°C | 40°C | 50°C | 60°C | 80°C | 90°C |

| 4x6 mm PVDF (Flex 2800) | 40 | 34 | 30 | 27 | 24.8 | 20 | 10 |

| 4x8 mm PVDF (Flex 2800) | 29 | 25.5 | 22 | 20 | 18 | 14.5 | 7.3 |

| 6x8 mm PVDF (Flex 2800) | 18 | 15.5 | 13.5 | 12.5 | 11.2 | 9 | 4.5 |

| 1/4 PE 230 | 17.6 | |

| 3/8 PE 230 | 10.6 | |

| 1/2 PE 230 | 10.6 | |